Et si vous entriez dans les coulisses de nos moulins ?

Meunier depuis 1919, cela fait plus de 100 ans que nous approvisionnons les boulangers français en farine de qualité que nous écrasons aujourd’hui dans nos 7 moulins régionaux. Pour pouvoir fabriquer ces farines, plusieurs étapes sont nécessaires avant même d’écraser le premier grain de blé.

Suivez-nous, on vous explique tout !

La réception des blés

Nous n’utilisons que des blés de haute qualité meunière. L’approvisionnement depuis les organismes stockeurs jusqu’à nos moulins peut être réalisé de plusieurs manières : en camion, en train, en péniche, et même via un bandeau relié directement du silo de la coopérative à l’un de nos moulins !

Chaque jour, ce sont de nombreuses tonnes de blés qui arrivent dans nos moulins. Comme nous portons une attention toute particulière à notre empreinte environnementale, nous privilégions l’acheminement par des transports écologiques, comme le train ou la péniche, chaque fois que cela est possible.

Notre moulin de la cité phocéenne, le seul doté d’un locotracteur électrique !

Au moulin de Marseille, 64% des blés arrivent en train !

Chaque semaine, un train approvisionne le moulin marseillais avec 1 320 tonnes de blés cultivés entre autres en Bourgogne-Franche-Comté et en Auvergne-Rhône-Alpes. Une fois que ce train est arrivé à destination – un embranchement ferroviaire se situe à 500 mètres du moulin – un locotracteur achemine les wagons jusqu’à la fosse de réception où les blés sont déchargés. Le blé est ensuite acheminé par aspiration – à raison de 80 tonnes par heure – vers le stockage du silo à blé en vue de son utilisation pour en extraire la farine. Un opérateur pilote par télécommande ce locotracteur pour l’opération de déchargement et un autre employé supervise la mise en stock au silo à blé. Le déchargement d’un train dure une vingtaine d’heures.

Le locotracteur : qu’est-ce que c’est ?

Un locotracteur est un engin ferroviaire utilisé pour la manœuvre des wagons. Dans notre cas, lorsque le train arrive à proximité du moulin, nous le divisons en chaînes de 6 ou 8 wagons. Le locotracteur va ensuite s’accrocher aux wagons et les emmener jusqu’à la fosse de réception. Historiquement, notre moulin de Marseille utilisait un locotracteur qui fonctionnait au fioul.

En 2022, après un premier test concluant, nous avons fait le choix de le remplacer par un locotracteur électrique, plus silencieux, plus fiable, plus économique et plus écologique. Nous avons alors formé cinq personnes au pilotage de cet engin. Ils ont tous reçu une habilitation, qu’ils doivent renouveler tous les trois ans.

La fiabilité est une caractéristique très importante de ce locotracteur. En effet, nous recevons chaque semaine un train chargé de 1300 tonnes de blés. Si le train n’est pas déchargé en temps et en heure, c’est toute une chaîne logistique qui en souffre avec des impacts qui peuvent rapidement devenir importants.

Le choix de l’électrique permet également de supprimer l’utilisation d’énergie fossile qui a un impact environnemental important. Le choix de l’électrique a été motivé par notre volonté de continuer nos efforts environnementaux. En favorisant la livraison des blés par des transports écologiques, nous nous engagions déjà en faveur de l’environnement. Aujourd’hui, en choisissant un locotracteur électrique, nous avons renforcé cet engagement et créé une chaîne complète d’acheminement responsable qui fait écho à notre démarche de développement durable Groupe : LINK.

« Le locotracteur électrique c’est l’avenir, cela nous permet de nous débarrasser des énergies fossiles.» José Torres, responsable approvisionnement blé au moulin de Marseille

Le moulin le plus proche de la Tour Eiffel, approvisionné par péniche !

Notre moulin de Paris-Gennevilliers est le plus proche de la tour Eiffel ! A seulement 7 kilomètres des portes de Paris, ce moulin à l’avantage d’être situé sur les bords de Seine.

Grâce à ce positionnement, les deux tiers des approvisionnements en blé se font par péniche et proviennent principalement d’Île-de-France via la Seine, l’Yonne, la Marne, l’Oise… Chaque année, ce sont 80 000 tonnes de blé qui sont acheminées par voie fluviale au moulin de Paris-Gennevilliers !

Une fois au moulin, le déchargement se fait grâce au vigan, une sorte de gros aspirateur qui aspire directement le blé à l’intérieur de la cale de la péniche et le dirige dans le moulin. Ce déchargement prend plusieurs heures.

Découvrez en vidéo les témoignages de Sébastien Picaud et Monsieur & Madame Maingault qui approvisionnent notre moulin en blé par péniche depuis de nombreuses années. Ils travaillent et vivent une vraie passion pour leurs bateaux et partagent des engagements forts pour l’environnement !

Le moulin de Verneuil, approvisionné directement via un bandeau relié au silo de la coopérative Valfrance !

Le moulin de Verneuil, en Seine et Marne, a la chance d’être situé juste à côté d’un des silos de la coopérative Valfrance. Pour profiter de cette proximité, un bandeau reliant directement le silo de la coopérative à notre moulin a été conçu en 1983.

Ce bandeau aérien, similaire a un tapis roulant, mesure 150 mètres de long. Quatre à cinq fois par semaine, ce bandeau permet d’acheminer des lots de 200 tonnes, soit entre 800 et 1000 tonnes de blés par semaine. Le débit de réception est de 100 tonnes par heure.

Ainsi l’approvisionnent via ce bandeau représente 45% des blés que nous recevons chaque année au moulin de Verneuil.

Ce bandeau, électrique, est un pas de plus dans notre démarche environnementale. En effet, ce système d’approvisionnement permet de réduire le transit par camion et de favoriser l’achat de blés de proximité.

Le contrôle qualité des blés

En amont, puis à l’arrivée des blés dans nos moulins, des contrôles sont réalisés. Ils nous permettent d’assurer à nos clients une qualité constante de farine autant au niveau organoleptique qu’au niveau sécurité alimentaire.

David Angelini, responsable QSE, José Torres, responsable approvisionnement et Gwenaëlle Merlo, responsable qualité produit, nous expliquent comment ont lieu ces processus de contrôle au moulin de Marseille.

« Un échantillon de tout ce qui rentre et de tout ce qui sort est analysé. » José Torres

Un premier contrôle qualité en amont de la livraison

Lorsque l’on programme un approvisionnement en blé, quel que soit son mode de transport, l’organisme stockeur nous fait parvenir un échantillon représentatif du lot qui nous sera livré pour le valider. Si celui-ci est validé, le blé peut alors prendre la route.

Afin de sécuriser nos approvisionnements en train (compte-tenu des volumes réceptionnés chaque semaine), un pré-contrôle au chargement depuis la coopérative est effectué par un organisme de contrôle agréé, ce qui permet de sécuriser et suivre le chargement en amont de sa réception.

Un second contrôle avant le déchargement

Quelle que soit la manière dont les blés sont acheminés au moulin, un échantillon est toujours contrôlé dès leur arrivée : un premier contrôle visuel ainsi qu’un tamisage permet de vérifier l’absence d’impureté et d’insecte. Ensuite, un contrôle avec un système infrarouge permet de vérifier la température, l’humidité et le poids spécifique du blé.

Si l’échantillon n’est pas conforme, le lot de blé n’entre pas dans le moulin. Dans le cas contraire, le déchargement peut avoir lieu et d’autres contrôles ont alors lieu en laboratoire.

Tout au long de la récolte, afin de répondre notamment aux exigences réglementaires, nos blés et farines font l’objet d’un suivi analytique spécifique au travers de notre Plan de Sécurité Alimentaire (PSA).

Des contrôles de la qualité du blé réguliers en laboratoire

Lors de cette étape, plusieurs échantillons d’un même lot sont amenés en laboratoire puis transformés rapidement en farine dans ce qu’on appelle un moulin d’essai. Il s’agit d’un moulin miniature qui va permettre de moudre une petite quantité de blé pour analyser ensuite la farine obtenue.

Il existe plusieurs types d’analyses à réaliser en fonction des blés livrés. Pour les blés de force, nous réalisons une analyse physico-chimique et une analyse rhéologique. Les blés panifiables seront soumis aux mêmes analyses ainsi qu’à une analyse technique supplémentaire.

L’analyse physico-chimique permet de contrôler l’humidité, le taux de cendre et le temps de chute (indice de germination du blé).

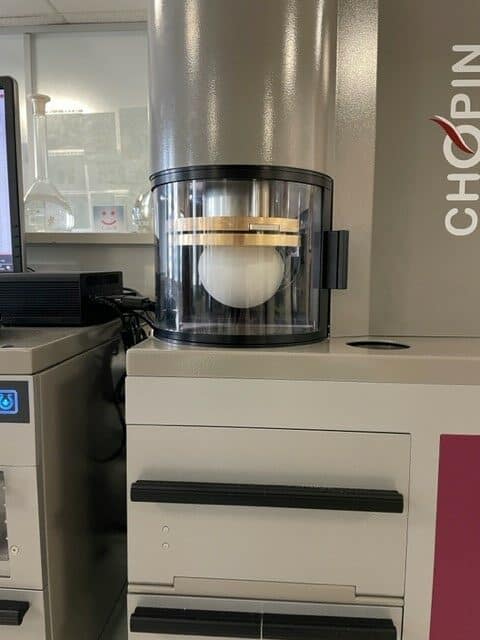

L’analyse rhéologique, à l’aide d’un alvéographe, mesure la valeur boulangère d’une farine pour s’assurer de la qualité des farines.

Ces deux premières analyses sont réalisées par des laborantin(e)s.

L’analyse technologique, consiste à faire subir à la farine toutes les étapes de la panification : pétrissage, fermentation, détente, façonnage, repos, cuisson. Le test de panification détermine la qualité boulangère des variétés de blés pures ou des mélanges, il permet d’optimiser une formulation et contrôle l’aptitude d’une farine à être commercialisée.

Cette dernière analyse est réalisée par un boulanger d’essai.

Toutes ces analyses nous permettre d’assurer une constance dans la qualité de la farine que nous produisons.

Focus sur les nouvelles récoltes :

Lors des nouvelles récoltes, les coopératives envoient à chacun de nos moulins des échantillons qui vont être analysés par nos équipes qualité. De ces analyses pourront être tirées des tendances sur la récolte et des conseils pour nos artisans boulangers que nous regroupons dans ce que nous appelons la Lettre de récolte.